|

|

2021-2022 Catalog [ARCHIVED CATALOG]

Course Descriptions

|

|

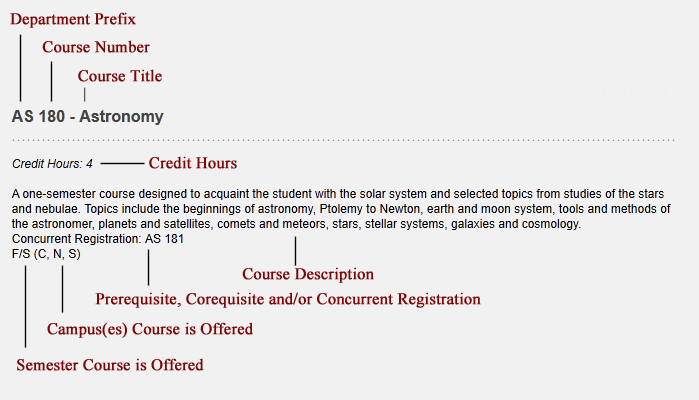

Key to Course Descriptions

Abbreviations

| (C) |

City Campus |

F/S |

Fall and Spring |

| (N) |

North Campus |

SS |

Summer Session |

| (S) |

South Campus |

F+ |

Offered every other Fall |

| F |

Fall |

S+ |

Offered every other Spring |

| S |

Spring |

N |

Non-Credit |

Course Outlines

Course outlines for all courses described in this catalog are available for viewing. To explore the general framework of a course design and view the expectations of student performance within a select course click on the link below. These descriptions provide the base upon which instructors build their own course syllabi for the individual sections offered by the academic departments. Individual sections may therefore vary somewhat from the descriptions given in the outlines.

Course Outlines

|

| |

Automotive Technology |

| |

-

AU 123 - Ford ASSET Automatic Transmissions and Transaxles Lab

Credit Hours: 2

Application of theoretical and practical aspects of preventative maintenance, troubleshooting, overhaul and repair of Ford Motor Company automobiles and light trucks.

Course Outcomes

Upon completion of the course the student will be able to:

- identify transmission/transaxle applications and types through the use of service manuals and codes. Competency will be base on lab performance and a practical test;

- demonstrate proper procedures for flushing transmission and/or transaxle cooling systems on Ford Motor Co. vehicles. Competency will be based on lab performance and activities;

- perform pressure test(s) and electrical scan tool checks for transmission/transaxle on Ford/L/M vehicles;

- completely disassemble, inspect and reassemble a RWD Transmission, FWD transaxle, both hydraulic and electronically controlled and show proper rebuilding procedures;

- demonstrate the proper OASIS and IDS diagnostic procedures related to Ford Motor Company automatic transmissions and transaxles;

- identify and show the proper use of the special tools, dial indicators, micrometers and feeler gauges needed to evaluate and overhaul automatic transmissions and transaxles. Competency will be based on lab activities; and

- perform internal and external adjustments as applicable to certain transmissions/transaxles. Competency will be based on lab activities and performance.

Concurrent Registration: AU 122

S (S)

|

| |

-

AU 123 - Mopar CAP Automatic Transmissions and Transaxles Lab

Credit Hours: 2

The operation and diagnosis of automatic transmissions and transaxles on Dodge, Chrysler and Jeep vehicles.

Course Outcomes

Upon completion of this course the student should be able to:

- research, test, and diagnose automatic transmission and transaxle problems;

- properly and safely remove and replace a transmission;

- research, disassemble, evaluate, and overhaul an automatic transmission;

- utilize the special tools required for transmission rebuilding; and

- application of the six-step diagnostic procedure to diagnose and repair problems in Chrysler vehicles equipped with automatic transmission/transaxle. Competency will be based on activities in the lab and a test(s) with a grade of at least 65%.

Concurrent Registration: AU 122

S (S)

|

| |

-

AU 124 - Ford ASSET Manual Transmissions and Transaxles

Credit Hours: 2

A study of Ford manual transmissions/ transaxles. Topics to include clutches, drivelines, differentials, theoretical and practical aspects of maintenance, troubleshooting and overhaul procedures.

Course Outcomes

Upon completion of the course the student will be able to:

- identify clutch systems components. Competency will be based on a test(s) with a grade of at least 65%;

- identify manual transmission and transaxle Powerflow Competency will be based on a test(s) with a grade of at least 65%;

- identify external component location on manual transmissions and transaxles. Competency will be based on a test(s) with a grade of at least 65%;

- identify component location of all parts located in the differential in either the front or rear of a Ford/L/M automobile or light truck. Competency will be based on activities in both the classroom/lab and a test(s) with a grade of at least 65%; and

- identify the components related to the transfer case, driveshaft and CV joint repair and maintenance. Competency is based on both classroom and lab activities plus a test(s) with a grade of at least 65%.

Concurrent Registration: AU 125

S (S)

|

| |

-

AU 124 - Mopar CAP Manual Transmissions and Transaxle

Credit Hours: 2

A study of manual transmissions, transaxles, transfer cases, and differentials. Topics include clutches, drivelines, theoretical and practical aspects of maintenance, trouble-shooting and overhaul procedures on Chrysler automobiles and light trucks.

Course Outcomes

Upon completion of this course the student will be able to:

- identify clutch systems components. Competency will be based on a test(s) with a grade of at least 65%;

- identify manual transmission and transaxle powerflow. Competency will be based on a test(s) with a grade of at least 65%;

- identify external component location on manual transmissions and transaxles. Competency will be based on a test(s) with a grade of at least 65%;

- identify component location of all parts located in the differential in either the front or rear of a DaimlerChrysler automobile or light truck. Competency will be based on activities in both the classroom/lab and a test(s) with a grade of at least 65%; and

- identify the components related to the transfer case, driveshaft and CV joint repair and maintenance. Competency is based on both classroom and lab activities plus a test(s) with a grade of at least 65%.

Concurrent Registration: AU 125

S (S)

|

| |

-

AU 125 - Ford ASSET Manual Transmissions and Transaxles Lab

Credit Hours: 2

The practical application of lecture topics pertaining to the identification, overhaul and maintenance of manual transmissions and transaxles, differentials and transfer cases. Topics to include clutches, drivelines, theoretical and practical aspects of maintenance, troubleshooting and overhaul procedures.

Course Outcomes

Upon completion of the course the student will be able to:

- perform clutch diagnosis and bleeding procedure for hydraulic clutch assembly. Competency will be based on performance in the lab and a test with a score of at least 65%;

- disassemble and reassemble a transmission and a transaxle for a Ford Motor Co. vehicles. All end play and turning torque measurements are to be taken and recorded. Competency will be determined on performance in the lab and a test with a grade of at least 65%;

- disassemble and reassemble a transfer case and check all specifications as outlined in the Ford Motor Co. service manual. Competency will be based on competency in the lab and a test(s) with a grade of at least 65%;

- diagnose and repair a driveshaft and a CV joint on a vehicle with noise, vibration and harshness. Competency will be based on performance in the lab and a test(s) with grade of at least 65%; and

- application of the six-step diagnostic procedure to diagnose and repair problems in Ford Motor Co. vehicles equipped with manual transmission/transaxle. Competency will be based on activities in the lab and a test(s) with a grade of at least 65%.

Concurrent Registration: AU 124

S (S)

|

| |

-

AU 125 - Mopar CAP Manual Transmission and Transaxle Lab

Credit Hours: 2

Practical application of lecture including the identification, overhaul and maintenance of manual transmissions and transaxles, differential and transfer cases. Topics to include clutches, drivelines, theoretical and practical aspects of maintenance, troubleshooting and overhaul procedures related to Chrysler vehicles.

Course Outcomes

Upon completion of the course the student will be able to:

- perform clutch diagnosis and bleeding procedure for hydraulic clutch assembly. Competency will be based on performance in the lab and a test with a score of at least 65%;

- disassemble and reassemble a transmission and a transaxle for a Chrysler vehicles. All end play and turning torque measurements are to be taken and recorded. Competency will be determined on performance in the lab and a test with a grade of at least 65%;

- disassemble and reassemble a transfer case and check all specifications as outlined in the Chrysler service manual. Competency will be based on competency in the lab and a test(s) with a grade of at least 65%;

- diagnose and repair a driveshaft and a CV joint on a vehicle with noise, vibration and harshness. Competency will be based on performance in the lab and a test(s) with grade of at least 65%; and

- application of the six-step diagnostic procedure to diagnose and repair problems in Chrysler vehicles equipped with manual transmission/transaxle. Competency will be based on activities in the lab and a test(s) with a grade of at least 65%.

Concurrent Registration: AU 124

S (S)

|

| |

-

AU 128 - Mopar CAP Cooperative Work Experience

Credit Hours: 1.5

Theory and instruction received in previous CAP courses, taught with a Chrysler emphasis, are applied to work in the sponsoring dealership.

Course Outcomes

Upon completion of the course the student will be able to:

- determine through diagnosis problems related to the engine;

- use test equipment to determine the parts and/or related components requiring repair or replacement;

- disassemble/inspect/repair and reassemble all Chrysler 4-, 6-, 8-cylinder engines (recent production);

- disassemble major engine components for adjustment, repair or replacement;

- perform replacement of external components such as water pumps, valve covers/gaskets, oil pan/gaskets, etc.;

- demonstrate a working knowledge and show the proper use of micrometers, torque wrench, dial indicators, etc.;

- remove and install and engine assembly and be able to disconnect/connect related hoses, cables and electrical connections;

- demonstrate a working knowledge of the Chrysler Onboard Diagnostic system (OBD II);

- demonstrate a basic knowledge of the Chrysler DRB III;

- show the ability to identify and locate the various sensors, potentiometers, etc. tied to computer related automobile operation;

- read and follow diagnostic charts designed to aid in locating and repairing computer related problems;

- show the ability to identify and use special tools needed to remove and install faulty computer related components. (EXAMPLE: special tool needed to replace oxygen sensor);

- demonstrate the ability to use a DVOM to test and determine whether a component is good/bad;

- repair processor and related wiring to Chrysler manufacturer specifications;

- roadtest a vehicle with diagnostic equipment attached to determine a drivability problem; and

- demonstrate a working knowledge of the Antilock Braking System(s) (ABS) used by Chrysler.

All Daimler-Chrysler CAP Co-ops are conducted with the student working with an “A” grade Technician. All the above objectives would be performed under the guidance of a professional to aid the student in the learning process as well as ensuring that all repairs and inspections are performed properly and at the level expected of the manufacturer.

Prerequisites: Enrollment in the Chrysler College Automotive Program (CAP).

Corequisites: AU 112, AU 113, AU 227, AU 228

S (S)

|

| |

-

AU 129 - Ford ASSET Cooperative Work Experience

Credit Hours: 1.5

Theory and instruction received in previous ASSET courses, taught with a Ford emphasis, are applied to work in the sponsoring dealership.

Course Outcomes

Upon completion of the course, the student will be able to:

- determine through diagnosis problems related to the engine;

- use test equipment to determine the parts and/or related components requiring repair or replacement;

- disassemble/inspect/repair and reassemble all Ford 4-, 6-, 8-cylinder engines (recent production);

- disassemble major engine components for adjustment, repair or replacement;

- perform replacement of external components such as waterpumps, valve covers/gaskets,oil pan/gaskets, etc.;

- demonstrate a working knowledge and show the proper use of micrometers, torque wrenches, dial indicators, etc.;

- remove and install and engine assembly and be able to disconnect/connect related hoses,cables and electrical connections, etc.;

- demonstrate a working knowledge of the Ford Onboard Diagnostic system (OBD II);

- demonstrate a basic knowledge of the Ford Integrated Diagnostic System (IDS);

- show the ability to identify and locate the various sensors, potentiometers, etc. tied to computer related automobile operation;

- read and follow diagnostic charts designed to aid in locating and repairing computer related problems;

- show the ability to identify and use special tools needed to remove and install faulty computer related components. (EXAMPLE: special tool needed to replace oxygen sensor);

- demonstrate the ability to use a DVOM to test and determine whether a component is good/bad;

- repair processor and related wiring to Ford manufacturer specifications;

- roadtest a vehicle with diagnostic equipment attached to determine a drivability problem; and

- demonstrate a working knowledge of the Antilock Braking System(s) (ABS) used by Ford Motor Company.

All Ford ASSET Coops are conducted with the student working with an “A” grade Technician. All the above objectives would be performed under the guidance of a professional to aid the student in the learning process as well as ensuring that all repairs and inspections are performed properly and at the level expected of the manufacturer.

Prerequisites: Enrollment in the Ford Automotive Student Service Educational Training Program (ASSET).

Corequisites: AU 112, AU 113, AU 227, AU 228

S (S)

|

| |

-

AU 130 - Suspension, Alignment and Brakes

Credit Hours: 2

Theoretical and practical study of the steering, suspension and brakes systems of an automobile. Included will be the diagnosis, repair and servicing of the above systems. (AU course required for Auto Body Major.)

Course Outcomes

Upon completion of this course, the student will be able to:

- describe the operation and function of the components of Non-servo & Duo-servo drum brake systems by naming the components and answering multiple choice, true/false questions and labeling a diagram on an exam;

- describe the operation and function of the components of fixed, floating and sliding disc brake caliper systems by answering multiple choice and/or true/false questions on an exam;

- understand the basic principles of hydraulics and how they apply to the operation and function of all the hydraulic components of the brake system. This includes the master cylinder, combination valve, ABS HCU, lines, hoses, calipers and wheel cylinders. An exam will be give with multiple choice and/or true false questions;

- understand terminology associated with automotive brake systems, wheels, tires and the principles of how a vehicle stops. Competency will be based on an exam with multiple choice and/or true/false questions;

- understand the terminology and concepts associated with steering, suspension and alignment of an automobile including but not limited to Camber, Caster, Toe, Steering Axis Inclination and Toe Out on turns and how they affect the stability of an automobile. Competency will be based upon an exam with multiple choice, true/false, fill in the blank and short answer questions;

- understand the function and operation of front suspension systems and any applicable terminology. An exam will be given for competency with multiple choice and true/false questions;

- understand the function and operation of rear suspension systems and any applicable terminology. An exam will be given for competency with multiple choice and true/false questions; and

- describe the operation and function of the steering systems of automobiles. This will include but not be limited to conventional and rack and pinion steering gears; power steering pumps, hoses and lines; steering columns and four wheel steering. Competency will be based on an exam with multiple choice and true/false questions.

Concurrent Registration: AU 131

S (S)

|

| |

-

AU 131 - Lab for Suspension, Alignment and Brakes

Credit Hours: 2

Practical application of lecture topics. Students will perform repair and adjustment of the steering, suspension and brake systems on modern automobiles and light trucks. (AU course required for Autobody Major.)

Course Outcomes

Upon completion of this course, the student will be able to:

- inspect a vehicles complete brake, steering and suspension system and determine condition of the components and if repair or replacement is necessary. A lab report and inspection form will be used to determine competency;

- repair a vehicles disc brake system. This will include but not be limited to the replacement of the brake pads, machining or replacement of the brake rotors, maintenance of the brake caliper and bleeding of the brake system. Competency will be based upon a student working in the lab and a lab report;

- repair a vehicles drum brake system. This will include but not be limited to the replacement of drum brake shoes, hardware, machining or replacement of the drums, adjustment of the parking brake and bleeding of the hydraulic system. The students will be assessed by their lab report and working in the lab;

- repair a vehicles hydraulic brake system. This could include but not be limited to master cylinder, disc brake caliper, wheel cylinder, ABS hydraulic control unit, lines and hoses. Competency will be based upon efforts in the lab and a written lab report;

- repair a vehicles wheel, tire and/or wheel bearing. This will include but not be limited to dismounting and mounting of a tire, repair of the tire, balancing of the assembly and the replacement or service to the wheel bearing. Lab work combined with a lab report will be used for assessment;

- repair the front and rear suspension of a vehicle. This could include the springs, shock absorbers, bushings, control arms ball joints or steering knuckles. Competency will be based on working in the lab and a lab report; and

- repair the steering system of a vehicle. This could include but not be limited to the repair or replacement of the steering gear, steering column, power steering pump, steering linkage and the alignment of all 4 wheels of the vehicle. Competency will be based on working in the lab and a lab report.

Concurrent Registration: AU 130

S (S)

|

| |

-

AU 150 - Introduction to Automotive Technology

Credit Hours: 2

A study in the advancements in the automotive industry, use and maintenance of equipment, safety in the shop and introduction to automotive systems.

Course Outcomes

Upon completion of this course, the student will be able to:

- have practical knowledge and understanding of safe shop procedures, precautions, and individual responsibilities associated with the right to know laws;

- identify the possible areas of employment within the automotive field, and utilize this information to determine a career objective;

- prepare an industry acceptable resume;

- explain the mission of the ASE, and the benefits of certification;

- visually identify various hand tools and shop equipment. Describe their proper use and required maintenance;

- demonstrate proper handling and usage of the oxy-acetylene torch;

- identify and categorize numerous fasteners used in the automotive trade areas;

- outline strategies and describe the various methods used for broken fastener extraction;

- access the available online information system to produce vehicle specific Information requested by the instructor; and

- locate manufacturer’s service schedules, explain their importance, and basically describe the procedures involved in very basic fluid maintenance.

F (S)

|

| |

-

AU 160 - Automotive Electrical

Credit Hours: 2

A study of the electrical system found in the modern-day automobile. Topics include the use of diagnostic meters, starting, charging, lighting, and accessory systems.

Course Outcomes

Upon completion of this course, the student will be able to:

- describe the behavior of electricity including voltage, resistance, current and Ohm’s Law;

- demonstrate proper use of diagnostic meters;

- describe simple, series, parallel and series parallel circuits;

- describe the operation of various common electrical circuits;

- read and understand wiring diagrams;

- demonstrate a proven diagnostic procedure; and

- utilize shop references to identify circuits and their operation.

Concurrent Registration: AU 161

F (S)

|

| |

-

AU 161 - Lab for Automotive Electrical

Credit Hours: 2

A practical application of the diagnosis and repair of the electrical system found in the modern-day automobile. Tasks include the use of diagnostic meters and other equipment to repair problems in the electrical system.

Course Outcomes

Upon completion of this course, the student will be able to:

- demonstrate proper use of diagnostic meters;

- diagnose and repair automotive electrical systems;

- evaluate automotive batteries, starting and charging systems;

- demonstrate proper battery service procedures;

- crimp, solder and heat shrink wiring and connectors;

- read and understand wiring diagrams;

- demonstrate a proven diagnostic procedure; and

- utilize shop references to identify circuits and their operation.

Concurrent Registration: AU 160

F (S)

|

| |

-

AU 162 - Automotive Engines

Credit Hours: 2

A study of the automobile engine. Topics include theoretical operation, construction, practical repair and troubleshooting of the four-, six- and eight-cylinder internal combustion engine.

Course Outcomes

Upon completion of this course the student will be able to:

- identify the location and function of all components in an internal combustion engine. Competency will be based on a test with a grade of at least 60%;

- using measuring devices to determine which components in an engine are defective and need to be replaced or repaired. Competency will be based on a test with a grade of at least 65%;

- understand repair procedures for machine shop functions related to the internal combustion engine. These include the reconditioning of crankshafts, connecting rods, cylinder heads and engine blocks. Competency will be based upon a test with a grade of at least 65%; and

- using the service manuals the student will be able to explain the proper procedures to reassemble an engine OHV/OHC. This should include timing, torque specs. and any special/unique steps specific to that engine. Competency will be based upon a test with a grade of at least 65%.

Concurrent Registration: AU 163

F (S)

|

| |

-

AU 163 - Lab for Automotive Engines

Credit Hours: 2

A practical study of the automotive engine including measuring and machining of the components related to the overhaul of a modern four-, six-, eight- or 10-cylinder internal combustion engine.

Course Outcomes

Upon completion of the course, the student will be able to:

- completely disassemble, inspect, measure, machine or replace all the internal components of an internal combustion engine. Testing prior to overhaul will include but not be limited to oil pressure, compression, and cylinder leak down. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- properly use all measuring devices as they apply to internal combustion engines. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- properly clean all components of an internal combustion engine and inspect for cracks or fatigue. Competency will be based on work effort in the lab and a practical test with a score of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in an internal combustion engine. Competency will be based on activities in the lab.

Concurrent Registration: AU 162

F (S)

|

| |

-

AU 170 - Automotive Brakes

Credit Hours: 2

Theoretical and practical study of the brake system. Areas covered include computerized brake systems, manual and power systems, drum and disc brakes, inspection and repair.

Course Outcomes

Upon completion of this course the student will be able to:

- understand the function of and proper repair of all components related to the operation of the disc brake systems. Competency will be based on a test with a score of at least 65%;

- understand the function and proper repair of all components related to the operation of the drum brake systems Competency will be based on a test with a grade of at least 65%;

- understand proper measuring techniques for the measurement of rotor thickness, drum diameter and wheel hub run out with the usage of a dial indicator, drum micrometer and an outside micrometer. Competency will be based on a test and classroom activities with a grade of at least 65%;

- understand proper machining techniques for both brake drums and rotors including both on and off the vehicle equipment. Competency will be based upon work quality in the lab combined with a test for a score of at least 65%;

- understand the operation and diagnostic procedures of all components related to anti-lock and/or traction control systems on a given vehicle. Competency will be based on classroom activities combined with a test for a grade of at least 65%; and

- become proficient using the Star Scan, DRB III and the proper service manual to diagnose the anti-lock brake system on a given vehicle. Competency will be based on classroom activities combined with a test for a grade of at least 60%.

Concurrent Registration: AU 171

S (S)

|

| |

-

AU 171 - Lab for Automotive Brakes

Credit Hours: 2

The practical application of the repair of the entire braking system on a modern automobile. Lab activities relate to the repair of mechanical, hydraulic, and electrical components

Course Outcomes

Upon completion of the course, the student should be able to:

- diagnose, inspect, remove and replace, rebuild, clean, adjust, test, and repair air conditioning and heating systems and components. The student will write a report for each required job task completed. To be considered correct, the report must follow the outline stated in the course evaluation;

- interpret manufacture’s manuals and specifications. The student will write up a report for each job task completed including the manufacturer’s procedures and specifications to be considered correct;

- select and use proper tools, equipment and materials needed to perform required job tasks. Evaluation will be base on observation by instructor and a written report by the student; and

- demonstrate the use of special equipment, such as the recovery/recycling/recharging station in the diagnosis and repairing of air conditioning systems and components. Evaluation will be base on observation by instructor.

Concurrent Registration: AU 170

S (S)

|

| |

-

AU 172 - Automatic Transmissions and Transaxles

Credit Hours: 2

Theoretical and practical aspects of preventive maintenance, troubleshooting, overhaul and repair are covered.

Course Outcomes

Upon completion of this course, the student should be able to:

- understand the fundamental operating principles of the automatic transmission and transaxle;

- research and identify specific transmissions and transaxles;

- identify other components and subsystems influencing the operation of the automatic transmission and transaxle;

- theoretically diagnose and repair problems affecting the performance of the automatic transmission and transaxle; and

- research and perform overhaul procedures on automatic transmissions and transaxles.

Concurrent Registration: AU 173

S (S)

|

| |

-

AU 173 - Lab for Automatic Transmissions and Transaxles

Credit Hours: 2

The diagnosis and repair of an automatic transmission and transaxle. Electrical, mechanical and hydraulic problems will be diagnosed and the overhaul of an automatic transmission or transaxle will be performed.

Course Outcomes

Upon completion of this course, the student should be able to:

- research, test, and diagnose automatic transmission and transaxle problems;

- properly and safely remove and replace a transmission;

- research, disassemble, evaluate, and overhaul an automatic transmission; and

- utilize the special tools required for transmission rebuilding.

Concurrent Registration: AU 172

S (S)

|

| |

-

AU 174 - Manual Transmissions and Transaxles

Credit Hours: 2

A study of manual transmissions/ transaxles. Topics to include clutches, drivelines, differentials, theoretical and practical aspects of maintenance, troubleshooting and overhaul procedures.

Course Outcomes

Upon completion of this course, the student should be able to:

- understand the fundamental operating principles of the manual transmission, transaxle, transfer case, differential, and clutch assembly;

- research and identify specific transmissions, transaxles, transfer cases, differentials, and clutch assemblies;

- identify other components and subsystems influencing the operation of the manual transmission and transaxle;

- theoretically diagnose problems affecting the performance of the manual transmission, transaxle, transfer case, differential, and clutch assembly; and

- research overhaul procedures on manual transmissions, transaxles, transfer cases, and differentials.

Concurrent Registration: AU 175

S (S)

|

| |

-

AU 175 - Lab for Manual Transmissions and Transaxles

Credit Hours: 2

Practical application of lecture topics. Students will perform diagonsitic and repair procedures related the clutch, manual transmission or transaxle, differential and transfer cases on modern vehicles. They will also perform transmission, transaxle, transfer case and differential overhaul procedures.

Course Outcomes

Upon completion of this course the student should be able to:

- develop a practical knowledge of the manual transmission, transaxle, transfer case, differential, and clutch assembly;

- research and identify specific transmissions, transaxles, transfer cases, differentials, and clutch assemblies;

- service components and subsystems influencing the operation of the manual transmission and transaxle;

- diagnose and repair problems affecting the performance of the manual transmission, transaxle, transfer case, differential, and clutch assembly; and

- perform overhaul procedures on manual transmissions, transaxles, transfer cases, and differentials.

Concurrent Registration: AU 174

S (S)

|

| |

-

AU 212 - Ford ASSET Fuel and Emissions

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the fuel emission control systems as found on Ford Motor Company vehicles.

Course Outcomes

Upon completion of the course, the student will be able to:

- describe 4/5 gas theory as they apply to Ford Motor Company vehicles. Competency will be based on a test with a grade of at least 65%;

- describe the operation and comparison of fuel injection systems as they apply to Ford Motor Company vehicles. Competency will be based on a test with a grade of at least 65%;

- describe the proper use of service and diagnostic manuals used with the repair of Ford Motor Company vehicles. Competency will be based on a test with a grade of at least 65%;

- describe the proper procedure for testing fuel and emission system components on Ford Motor Company vehicles. Competency will be based on activities in the classroom with participation in question and answer sessions; and

- apply the six-step diagnostic procedure to diagnose and repair problems in Ford Motor Company fuel and emissions systems. Competency will be based on activities in the classroom and a test with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 213, AU 218, AU 219, AU 224, AU 225

S (S)

|

| |

-

AU 212 - Mopar CAP Fuel and Emissions

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the fuel emission control systems as found on Chrysler vehicles.

Course Outcomes

Upon completion of this course the student will be able to:

- describe 5 gas theory as they apply to Chrysler vehicles. Competency will be based on a test with a grade of at least 65%;

- describe the operation and comparison of fuel injection systems as they apply to Chrysler vehicles. Competency will be based on a test with a grade of at least 65%;

- describe the proper use of service and diagnostic manuals used with the repair of Chrysler vehicles. Competency will be based on a test with a grade of at least 65%;

- describe the proper procedure for testing fuel and emission system components on Chrysler vehicles. Competency will be based on activities in the classroom with participation in question and answer sessions; and

- apply the six-step diagnostic procedure to diagnose and repair problems in Chrysler fuel and emissions systems. Competency will be based on activities in the classroom and a test with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 213, AU 218, AU 219, AU 224, AU 225

S (S)

|

| |

-

AU 213 - Ford ASSET Fuel and Emissions Systems Lab

Credit Hours: 2

Application and theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the fuel and emissions systems as found on Ford Motor Company vehicles.

Course Outcomes

Upon completion of the course, the student will be able to:

- perform test to prove the effects of fuel and emission system function as it relates to 4 and 5 gas analyzers as it applies on Ford/L/M vehicles. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- test the components related to the entire operation of fuel injection systems as they are found on Ford/Lincoln/Mercury vehicles. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- properly use service and diagnostic manuals to aid with the repair of Ford/Lincoln/Mercury vehicles. Competency will be based on work performed in the lab and a test with a grade of at least 65%.

- perform the proper procedure for testing emission system components on Ford/Lincoln/Mercury vehicles. Competency will be based on work performance in the lab and a test with a grade of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in Ford/Lincoln/ Mercury fuel and emission systems. Competency will be based on activities in the lab and classroom combined with a test for a grade of at least 65%.

Concurrent Registration: AU 212, AU 218, AU 219, AU 224, AU 225

S (S)

|

| |

-

AU 213 - Mopar CAP Fuel and Emissions Systems Lab

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the fuel and emissions systems as found on Chrysler vehicles.

Course Outcomes

Upon completion of this course the student will be able to:

- perform test to prove the effects of fuel and emission system function as it relates to 4 and 5 gas analyzers as it applies on Chrysler vehicles. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- test the components related to the entire operation of fuel injection systems as they are found on Chrysler vehicles. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- properly use service and diagnostic manuals to aid with the repair of Chrysler vehicles. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- perform the proper procedure for testing emission system components on Chrysler vehicles. Competency will be based on work performance in the lab and a test with a grade of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in Chrysler fuel and emission systems. Competency will be based on activities in the lab and classroom combined with a test for a grade of at least 65%.

Concurrent Registration: AU 212, AU 218, AU 219, AU 224, AU 225

S (S)

|

| |

-

AU 215 - Ford ASSET New York State Inspection Lab

Credit Hours: 1

Conducting vehicle safety/emissions inspections according to New York State DMV guidelines.

Course Outcomes

Upon completion of the course the student will be able to:

- identify the requirements necessary to operate an approved NYS Inspection station, including space requirements, special tools, postings and all required paper work. Competency will be based on a test(s) with a grade of at least 65%;

- individual requirements including work application process, work experience requirements, testing, and licensee duties as an inspector. Competency will be based on a test(s) with a grade of at least 65%;

- types of vehicles required to be inspected and the different requirements for these vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- perform the safety inspection on a vehicle to include service brake system, parking brake, tires, steering, suspension, front end, chassis, lighting and reflectors, windshield and other glass, mirrors, windshield wipers, horn, seat belts and fuel leaks. Competency will be based on lab performance, worksheets and test(s) with a grade of at least 65%;

- perform an emissions inspection on 1996 and newer vehicles including emissions inspection procedures, pre-emissions inspection safety check, effect of failure of OBD II low enhanced emission test, and emission control devices. Competency will be based on lab performance, worksheets and test(s) with a grade of at least 65%;

- issuance of certificates of inspection and inspection rejection notices and replacement of inspection stickers. Competency will be based on test(s) with a minimum grade of at least 65%;

- perform the required paperwork for ordering new inspection certificates, returning old certificates for credit, rejection certificates, replacement certificates, refunds and credit. Competency will be based on test(s) with a grade of at least 65%; and

- set up and adjustment of headlamps as required using both headlamp aimers and the aiming screen. Including the replacement of aiming components as needed to properly perform the aiming tasks. Competency will be based on lab performance and evaluation.

Prerequisites: AU 110, AU 111, AU 120, AU 121, AU 220, AU 221, AU 227, AU 228

F (S)

|

| |

-

AU 215 - Mopar CAP New York State Inspection Lab

Credit Hours: 1

The current New York State inspection regulations and procedures. Safety and emissions procedures in regards to the inspection and testing of components related to state inspections.

Course Outcomes

Upon completion of this course the student will be able to:

- identify the requirements necessary to operate an approved NYS Inspection station including space requirements, special tools, postings and all required paper work. Competency will be based on a test(s) with a grade of at least 65%;

- individual requirements including work application process, work experience requirements, testing, and licensee duties as an inspector. Competency will be based on a test(s) with a grade of at least 65%;

- types of vehicles required to be inspected and the different requirements for these vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- perform the safety inspection on a vehicle to include service brake system, parking brake, tires, steering, suspension, front end, chassis, lighting and reflectors, windshield and other glass, mirrors, windshield wipers, horn, seat belts and fuel leaks. Competency will be based on lab performance, worksheets and test(s) with a grade of at least 65%;

- perform an emissions inspection on 1996 and newer vehicles including emissions inspection procedures, pre-emissions inspection safety check, effect of failure of OBD II low enhanced emission test, and emission control devices. Competency will be based on lab performance, worksheets and test(s) with a grade of at least 65%;

- issuance of certificates of inspection and inspection rejection notices and replacement of inspection stickers. Competency will be based on test(s) with a minimum grade of at least 65%;

- perform the required paperwork for ordering new inspection certificates, returning old certificates for credit, rejection certificates, replacement certificates, refunds and credit. Competency will be based on test(s) with a grade of at least 65%; and

- set up and adjustment of headlamps as required using both headlamp aimers and the aiming screen. Including the replacement of aiming components as needed to properly perform the aiming tasks. Competency will be based on lab performance and evaluation.

Prerequisites: AU 110, AU 111, AU 120, AU 121, AU 220, AU 221, AU 227, AU 228

F (S)

|

| |

-

AU 218 - Ford ASSET Engine Performance

Credit Hours: 2

Application of theoretical and practical application for theuse of modern testing equipment and techniques for diagnosing and servicing the ignition and engine control systems as found on the Ford Motor Co. automobiles and light trucks.

Course Outcomes

Upon completion of the course the student will be able to:

- identify and describe the operation of engine management systems as they apply to Ford Motor Company vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- identify, locate and interpret the operation of the components used in the engine management systems as they apply to Ford Motor Co. vehicles. Competency will be based on test(s) with a grade of at least 65%;

- demonstrate proper use of service and diagnostic manuals used with the repair of Ford/Lincoln/Mercury vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate a diagnostic strategy for engine management and drivability concerns on Ford Motor Company vehicles. Competency will be based on activities in the classroom with participation in question and answer sessions; and

- apply the six-step diagnostic procedure to diagnose and repair problems on Ford Motor Co. vehicles. Competency will be based on activities in the classroom and a test(s) with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 219, AU 224, AU 225

S (S)

|

| |

-

AU 218 - Mopar CAP Automotive Engine Performance

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the ignition and engine control systems as found on the Chrysler automobiles and light trucks.

Course Outcomes

Upon completion of this course the student will be able to:

- identify and describe the operation of engine management systems as they apply to Chrysler vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- identify, locate and interpret the operation of the components used in the engine management systems as they apply to Chrysler vehicles. Competency will be based on test(s) with a grade of at least 65%;

- demonstrate proper use of service and diagnostic manuals used with the repair of Chrysler vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate a diagnostic strategy for engine management and drivability concerns on Chrysler vehicles. Competency will be based on activities in the classroom with participation in question and answer sessions; and

- apply the six-step diagnostic procedure to diagnose and repair problems on Chrysler vehicles. Competency will be based on activities in the classroom and a test(s) with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 219, AU 224, AU 225

S (S)

|

| |

-

AU 219 - Ford ASSET Engine Performance Lab

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the ignition and engine control systems as found on Ford Motor Company automobiles and light trucks.

Course Outcomes

Upon completion of the course, the student will be able to:

- identify and test the operation of engine management systems as they apply to Ford Motor Company vehicles. Competency will be based on work performed in the lab and a test(s) with a grade of at least 65%;

- identify, locate and test the operation of the components used in Ford/Lincoln/Mercury ignition systems. Competency will be based on work performed in the lab and a test(s) with a grade of at least 65%;

- demonstrate proper use of service and diagnostic manuals used with the repair of Ford/Lincoln/Mercury automobiles and light trucks. Competency will be based on work performed in the lab and a test(s) with a score of at least 65%;

- perform proper mechanical diagnostics to determine the internal condition of an internal combustion engine. These will include compression test (both wet and dry), cylinder leak down and the comparison of the results. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in Ford Motor Co. engine performance areas. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 218, AU 224, AU 225

S (S)

|

| |

-

AU 219 - Mopar CAP Automotive Engine Performance Lab

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the ignition and engine control systems as found on Chrysler automobiles and light trucks.

Course Outcomes

Upon completion of this course the student will be able to:

- identify and test the operation of engine management systems as they apply to Chrysler vehicles. Competency will be based on work performed in the lab and a test(s) with a grade of at least 65%;

- identify, locate and test the operation of the components used in Chrysler ignition systems. Competency will be based on work performed in the lab and a test(s) with a grade of at least 65%;

- demonstrate proper use of service and diagnostic manuals used with the repair of Chrysler automobiles and light trucks. Competency will be based on work performed in the lab and a test(s) with a score of at least 65%;

- perform proper mechanical diagnostics to determine the internal condition of an internal combustion engine. These will include compression test (both wet and dry), cylinder leak down and the comparison of the results. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in Chrysler engine performance areas. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 218, AU 224, AU 225

S (S)

|

| |

-

AU 220 - Ford ASSET Alignment and Suspension

Credit Hours: 2

Application of theoretical and practical applications for the use of modern testing equipment and techniques for diagnosing and servicing the alignment and suspension system as found on the modern Ford Motor Company automobiles and light trucks.

Course Outcomes

Upon completion of this course, the student will be able to:

- identify and describe the operation of front suspension systems as they are found on modern automobile and light trucks, including alignment and adjustment procedures. Competency will be based on a test with a grade of at least 65%;

- identify and describe the operation of the rear suspension systems as they are found on the modern automobile and light truck, including alignment and adjustment procedures. Competency will be based on a test with a grade of at least 65%;

- understand the use of different spring construction and shapes including composite and tapered springs. Competency will be based on a test with a grade of at least 65%;

- identify and describe the operation of the different types of steering systems as found on modern automobiles and light trucks. Competency will be based on a test with a grade of at least 65%;

- identify and describe the operation of power steering systems and components as found on modern vehicles. Competency will be based on activities in the classroom and a test with a grade of at least 65%; and

- understand test procedures for testing the proper operation of the power steering pumps and gear boxes. Competency will be based on classroom and lab activities.

Concurrent Registration: AU 221

F (S)

|

| |

-

AU 220 - Mopar CAP Automotive Alignment and Suspension

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the steering and suspension systems as found on modern Chrysler automobiles and light trucks.

Course Outcomes

Upon completion of this course the student will be able to:

- identify and describe the operation of front suspension systems as they are found on modern automobile and light trucks, including alignment and adjustment procedures. Competency will be based on a test with a grade of at least 65%;

- identify and describe the operation of the rear suspension systems as they are found on the modern automobile and light truck, including alignment and adjustment procedures. Competency will be based on a test with a grade of at least 65%;

- understand the use of different spring construction and shapes including composite and tapered springs. Competency will be based on a test with a grade of at least 65%;

- identify and describe the operation of the different types of steering systems as found on modern automobiles and light trucks. Competency will be based on a test with a grade of at least 65%;

- identify and describe the operation of power steering systems and components as found on modern vehicles. Competency will be based on activities in the classroom and a test with a grade of at least 65%; and

- understand test procedures for testing the proper operation of the power steering pumps and gear boxes. Competency will be based on classroom and lab activities.

Concurrent Registration: AU 221

F (S)

|

| |

-

AU 221 - Ford ASSET Alignment and Suspension Lab

Credit Hours: 2

Application of theoretical and practical application for the useof modern testing equipment and techniques for diagnosing and servicing the alignment and suspension systems as found on the modern Ford Motor Company automobile and light truck.

Course Outcomes

Upon completion of the course the student will be able to:

- completely remove and replace the entire front suspension and steering systems and perform a proper wheel alignment on a modern automobile or light truck. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- completely remove and replace the entire rear suspension system and perform a proper wheel alignment on a modern automobile or light truck. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- test the power steering pump and steering gear for proper operation and leaks on a modern vehicle. Competency will be based on work performed in the lab and a grade of at least 65%;

- perform a four wheel alignment on a modern vehicle that has an adjustable and a non-adjustable rear suspension. Competency will be based on performance in the lab and a written test with a score of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in the alignment and suspension area of a modern automobile or light truck. Competency will be based on performance in the lab and a test with a grade of at least 65%.

Concurrent Registration: AU 220

F (S)

|

| |

-

AU 221 - Mopar CAP Automotive Alignment and Suspension Lab

Credit Hours: 2

Application of theoretical and practical application for the use of modern testing equipment and techniques for diagnosing and servicing the alignment and suspension systems as found on modern Chrysler automobiles and light trucks.

Course Outcomes

Upon completion of this course the student will be able to:

- completely remove and replace the entire front suspension and steering systems and perform a proper wheel alignment on a modern automobile or light truck. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- completely remove and replace the entire rear suspension system and perform a proper wheel alignment on a modern automobile or light truck. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- test the power steering pump and steering gear for proper operation and leaks on a modern vehicle. Competency will be based on work performed in the lab and a grade of at least 65%;

- perform a four wheel alignment on a modern vehicle that has an adjustable and a non-adjustable rear suspension. Competency will be based on performance in the lab and a written test with a score of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in the alignment and suspension area of a modern automobile or light truck. Competency will be based on performance in the lab and a test with a grade of at least 65%.

Concurrent Registration: AU 220

F (S)

|

| |

-

AU 222 - Ford ASSET Air Conditioning and Heating

Credit Hours: 2

Modern cooling, heating and air conditioning. The diagnosing and repair of temperature control and air flow control of the heating and cooling systems.

Course Outcomes

Upon completion of the course, the student will be able to:

- identify the differences in air conditioning systems used on modern vehicles, including R-12, R-134a, type of drier and if an orifice tube or expansion valve. Competency will be based on a test with a grade of at least 65%;

- identify and describe the procedure for attaching manifold gauges to an air conditioning system and tell what proper pressure should be. Competency will be based on a test with a grade of at least 65%;

- describe the function of all of the components in an air conditioning system. Competency will be based on a grade of at least 65%;

- identify and describe the operation and testing of the control head on modern vehicles. Competency will be based on a test and a score of at least 65%;

- understand the operation of the electrical parts of the air conditioning and heating system. Competency will be based on a test with a grade of at least 65%; and

- understand and be able to perform test procedure on the cooling system of the vehicle as it relates to the heater system. Competency will be based on classroom and lab activities and a test with a grade of at least 65%.

Concurrent Registration: AU 223

F (S)

|

| |

-

AU 222 - Mopar Automotive Air Conditioning and Heating

Credit Hours: 2

Modern cooling, heating and air conditioning. The diagnosing and repair of temperature and air flow control of the heating and cooling systems.

Course Outcomes

Upon completion of this course the student will be able to:

- identify the differences in air conditioning systems used on modern vehicles, including R-12, R-134a, type of drier and if an orifice tube or expansion valve. Competency will be based on a test with a grade of at least 65%;

- identify and describe the procedure for attaching manifold gauges to an air conditioning system and tell what proper pressure should be. Competency will be based on a test with a grade of at least 65%;

- describe the function of all of the components in an air conditioning system. Competency will be based on a grade of at least 65%;

- identify and describe the operation and testing of the control head on modern vehicles. Competency will be based on a test and a score of at least 65%;

- understand the operation of the electrical parts of the air conditioning and heating system. Competency will be based on a test with a grade of at least 65%; and

- understand and be able to perform test procedure on the cooling system of the vehicle as it relates to the heater system. Competency will be based on classroom and lab activities and a test with a grade of at least 65%.

Concurrent Registration: AU 223

F (S)

|

| |

-

AU 223 - Ford ASSET Air Conditioning and Heating Lab

Credit Hours: 2

Modern cooling, heating and air conditioning. The diagnosing and the repair of temperature control and air flow control of the heating and cooling systems.

Course Outcomes

Upon completion of the course, the student will be able to:

- evacuate and recharge an air conditioning system. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- attach manifold gauges to a vehicle and determine the problem with the vehicle. Proceed to completely remove and replace all components in the heating and air conditioning system on the vehicle. Competency will be based on work performed in lab and a test with a grade of at least 65%;

- test and flush the cooling system of a modern vehicle. Included in the testing procedure is the quality of the coolant, temperature at which the thermostat opens and the cooling fan(s) turn on, and the flushing and recycling of the anti-freeze in the vehicle. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- using the computerized testing equipment, diagnose problems with the climate control system on a modern automobile or light truck. Competency will be based on performance in the lab and a test with a grade of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in the air conditioning and heating areas of a modern vehicle. Competency will be based on work performed in the lab and a test with a grade of at least 65%.

Concurrent Registration: AU 222

F (S)

|

| |

-

AU 223 - Mopar CAP Automotive Air Conditioning and Heating Systems Lab

Credit Hours: 2

Modern cooling, heating and air conditioning. The diagnosing and the repair of temperature control and air flow control of the heating and cooling systems.

Course Outcomes

Upon completion of this course the student will be able to:

- evacuate and recharge an air conditioning system. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- attach manifold gauges to a vehicle and determine the problem with the vehicle. Proceed to completely remove and replace all components in the heating and air conditioning system on the vehicle. Competency will be based on work performed in lab and a test with a grade of at least 65%;

- test and flush the cooling system of a modern vehicle. Included in the testing procedure is the quality of the coolant, temperature at which the thermostat opens and the cooling fan(s) turn on, and the flushing and recycling of the anti-freeze in the vehicle. Competency will be based on work performed in the lab and a test with a grade of at least 65%;

- using the computerized testing equipment, diagnose problems with the climate control system on a modern automobile or light truck. Competency will be based on performance in the lab and a test with a grade of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in the air conditioning and heating areas of a modern vehicle. Competency will be based on work performed in the lab and a test with a grade of at least 65%.

Concurrent Registration: AU 222

F (S)

|

| |

-

AU 224 - Ford ASSET Computer Assisted Mechanisms

Credit Hours: 2

Application of theoretical and practical applications of computers in the control of functions on Ford Motor Company vehicles.

Course Outcomes

Upon completion of the course, the student will be able to:

- identify and describe the operation of computer controlled components as they apply to Ford Motor Company vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate the proper use of the Integrated Diagnostic System (IDS), OASIS and other diagnostic equipment as they apply to Ford Motor Company vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate proper use of service and diagnostic manuals used with the repair of Ford Motor Co. vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate a diagnostic strategy for the engine management, fuel control and drivability concerns on Ford/Lincoln/Mercury vehicles. Competency will be based on activities in the classroom and a test(s) with a grade of at least 65%;

- apply the SSCC diagnostic procedure to diagnose and repair problems in Ford computer controlled systems. Competency will be based on activities in the classroom and a test(s) with a grade of at least 65%;

- describe the need for On Board Diagnostics II (OBD II) as it applies to Ford/Lincoln/Mercury and other manufacturers. Competency will be based on classroom activities and a test(s) with a grade of at least 65%;

- describe the proper procedure for erasing codes on a OBD II vehicle. Competency will be based on classroom and lab activities; and

- describe proper data recording procedures on Ford/Lincoln/Mercury vehicles. Competency will be based on activities in the classroom as well as a test(s) with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 218, AU 219, AU 225

S (S)

|

| |

-

AU 224 - Mopar CAP Computer Controlled Mechanisms

Credit Hours: 2

Application of theoretical and practical applications of computers in the control of functions on Chrysler vehicles.

Course Outcomes

Upon completion of this course the student will be able to:

- identify and describe the operation of computer controlled components as they apply to Chrysler vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate the proper use of the Diagnostic Readout Box III (DRB III), the Mopar Diagnostic System (MDS) and other diagnostic equipment as they apply to Chrysler vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate proper use of service and diagnostic manuals used with the repair of Chrysler vehicles. Competency will be based on a test(s) with a grade of at least 65%;

- demonstrate a diagnostic strategy for the engine management, fuel control and drivability concerns on Chrysler vehicles. Competency will be based on activities in the classroom and a test(s) with a grade of at least 65%;

- apply the six-step diagnostic procedure to diagnose and repair problems in Chrysler computer controlled areas. Competency will be based on activities in the classroom and a test(s) with a grade of at least 65%;

- describe the need for On Board Diagnostics II (OBD II) as it applies to Chrysler and other manufacturers. Competency will be based on classroom activities and a test(s) with a grade of at least 65%;

- describe the proper procedure for erasing codes on a OBD II vehicle. Competency will be based on classroom and lab activities; and

- describe proper data recording procedures on Chrysler vehicles. Competency will be based on activities in the classroom as well as a test(s) with a grade of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 218, AU 219, AU 225

S (S)

|

| |

-

AU 225 - Ford ASSET Computer Assisted Mechanisms Lab

Credit Hours: 2

Application of theoretical and practical application of computers in the control of functions on Ford Motor Company vehicles.

Course Outcomes

Upon completion of the course the student will be able to:

- analyze and test the operation of computer controlled components as they apply to modern vehicles. Competency will be based on performance in the lab combined with a test with a grade of at least 65%;

- demonstrate the proper use of the Integrated Diagnostic System (IDS), the Ford Oasis and other diagnostic equipment on Ford Motor Company and other vehicles.Competency will be based on performance in the lab and a test(s) with a grade of at least 65%;

- demonstrate the proper use of service and diagnostic manuals used with the repair of modern vehicles. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%;

- demonstrate a diagnostic strategy for engine management, fuel control and drivability on a modern vehicle. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%;

- application of the SSCC procedure to diagnose and repair problems in Ford Motor Company computer controlled vehicle. Competency will be based on activities in the lab and a test(s) with a grade of at least 65%;

- perform diagnostic procedures on vehicles that have provisions for On Board Diagnostics II (OBD II). Competency will be graded on activities in the lab and a test(s) with a grade of at least 65%;

- perform the proper procedure for erasing codes on an OBD II vehicle. Competency will be based on classroom an lab activities; and

- perform proper data recording procedures on applicable vehicles. Competency will be based on activities in the lab as well as a test(s) with a score of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 218, AU 219, AU 224

S (S)

|

| |

-

AU 225 - Mopar CAP Computer Assisted Mechanisms Lab

Credit Hours: 2

Application of theoretical and practical application of computers in the control of functions on Chrysler vehicles.

Course Outcomes

Upon completion of this course the student will be able to:

- analyze and test the operation of computer controlled components as they apply to modern vehicles. Competency will be based on performance in the lab combined with a test with a grade of at least 65%;

- demonstrate the proper use of the Diagnostic Readout Box (DRB III), the Mopar Diagnostic System (MDS) and other diagnostic equipment on Chrysler and other vehicles. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%;

- demonstrate the proper use of service and diagnostic manuals used with the repair of modern vehicles. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%;

- demonstrate a diagnostic strategy for engine management, fuel control and drivability on a modern vehicle. Competency will be based on performance in the lab and a test(s) with a grade of at least 65%;

- application of the six-step diagnostic procedure to diagnose and repair problems in Chrysler computer controlled vehicle. Competency will be based on activities in the lab and a test(s) with a grade of at least 65%;

- perform diagnostic procedures on vehicles that have provisions for On Board Diagnostics II (OBD II). Competency will be graded on activities in the lab and a test(s) with a grade of at least 65%;

- perform the proper procedure for erasing codes on an OBD II vehicle. Competency will be based on classroom and lab activities; and

- perform proper data recording procedures on applicable vehicles. Competency will be based on activities in the lab as well as a test(s) with a score of at least 65%.

Prerequisites: AU 110, AU 111, AU 112, AU 113, AU 227, AU 228

Concurrent Registration: AU 212, AU 213, AU 218, AU 219, AU 224

S (S)

|

| |

-

AU 227 - Ford ASSET Automotive Electronics

Credit Hours: 2

Application of theoretical and practical study of the electronic systems in the modern automobile. Related to the operation of all computers and components and the proper repair of them.

Course Outcomes

Upon completion of the course, the student will be able to:

- identify and describe the specific purpose and operation of input (sensing), control and output (load) devices. As they apply to modern vehicles. Competency will be based on a test with a grade of at least 65%;

- identify the general function of electronic controllers/computers as they apply to modern vehicles. Competency will be based on a test with a grade of at least 65%;

- identify how specific electrical components interact within an electrical system. Competency will be based on a test with a grade of at least 65%;

- test specific electrical components as they apply to modern vehicles. Competency will be based on activities in the classroom with participation in question and answer sessions; and

- apply the six-step diagnostic procedure to diagnose and repair problems in electrical circuits. Competency will be based on activities in the classroom with participation inquestion and answer sessions.

Prerequisites: AU 110, AU 111

Concurrent Registration: AU 228

S (S)

|

| |

-

AU 227 - Mopar CAP Automotive Electronics

Credit Hours: 2

Application of theoretical and practical study of the electronic systems in the modern automobile. Related to the operation of all computers and components and the proper repair of them.

Course Outcomes

Upon completion of this course the student will be able to:

- identify and describe the specific purpose and operation of input (sensing), control and output (load) devices. As they apply to modern vehicles. Competency will be based on a test with a grade of at least 65%;

- identify the general function of electronic controllers/computers as they apply to modern vehicles. Competency will be based on a test with a grade of at least 65%;

- identify how specific electrical components interact within an electrical system. Competency will be based on a test with a grade of at least 65%;

- test specific electrical components as they apply to modern vehicles. Competency will be based on activities in the classroom with participation in question and answer sessions; and

- apply the six-step diagnostic procedure to diagnose and repair problems in electrical circuits. Competency will be based on activities in the classroom with participation in question and answer sessions.

Prerequisites: AU 110, AU 111

Concurrent Registration: AU 228

S (S)

|

| |

-

AU 228 - Ford ASSET Automotive Electronics Lab

Credit Hours: 2

Application of theoretical and practical study of the electronic systems in modern automobiles. Related to the operation of all computers and components and the proper diagnosis/repair.

Course Outcomes

Upon completion of the course, the student will be able to:

- identify and describe the specific purpose and operation of input (sensing), control and output (load) devices as they apply to modern vehicles. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- identify the general function of electronic controllers/computers as they apply to modern vehicles. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- identify how specific electrical components interact within an electrical system. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- test specific electrical components as they apply to modern vehicles. Competency will be based on work effort in the lab and a practical test with a score of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in the electrical circuits. Competency will be based on activities in the lab.

Prerequisites: AU 110, AU 111

Concurrent Registration: AU 227

S (S)

|

| |

-

AU 228 - Mopar CAP Automotive Electronics Lab

Credit Hours: 2

Application of theoretical and practical study of the electronic systems in modern automobiles. Related to the operation of all computers and components and the proper repair of them.

Course Outcomes

Upon completion of this course the student will be able to:

- identify and describe the specific purpose and operation of input (sensing), control and output (load) devices as they apply to modern vehicles. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- identify the general function of electronic controllers/computers as they apply to modern vehicles. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- identify how specific electrical components interact within an electrical system. Competency will be based on work effort in the lab and a practical test with a score of at least 65%;

- test specific electrical components as they apply to modern vehicles. Competency will be based on work effort in the lab and a practical test with a score of at least 65%; and

- apply the six-step diagnostic procedure to diagnose and repair problems in the electrical circuits. Competency will be based on activities in the lab.

Prerequisites: AU 110, AU 111

Concurrent Registration: AU 227

S (S)

|

| |

-

AU 238 - Mopar CAP Cooperative Work Experience

Credit Hours: 1.5

Theory and instruction received in previous CAP courses, taught with a Chrysler emphasis, are applied to work in the sponsoring dealership.

Course Outcomes

Upon completion of this course the student will be able to:

- inspect the automobile heating system and related components to ensure proper operation;

- inspect the automobile air conditioning system and related components to ensure proper operation;

- inspect and where needed repair or replace heating or air conditioning components;

- following Chrysler procedures flush the cooling system and refill with proper coolant;

- following Chrysler procedures the student will evacuate/refill or charge the A/C system using approved refrigerant;

- use appropriate service manuals/software to assist in diagnosis and repair of the air conditioning/heating system;

- roadtest a vehicle to assist in determining if a drivability problem is related to the steering or suspension systems;

- perform a pre-alignment inspection to determine if parts or components of the steering/suspension system need to be adjusted or replaced;

- properly replace worn or defective parts or components of the steering/suspension systems;

- replace tires and balance as required. Where necessary replace wheels that after testing prove to be defective;

- properly perform front wheel and, where needed, rear wheel alignments to correct drivability problems;

- use appropriate service manuals/software to assist in the diagnosis and repair of problems associated to the suspension/steering systems;

- perform a New York State Inspection on a vehicle brought to the dealer for yearly inspection;

- perform the necessary repairs and adjustments as required by New York State Department of Motor Vehicles;

- write up the appropriate paperwork for a vehicle that has either passed or failed inspection; and

- demonstrate an understanding of the NYS Inspection manual and its contents as far as performing a proper and legal inspection.